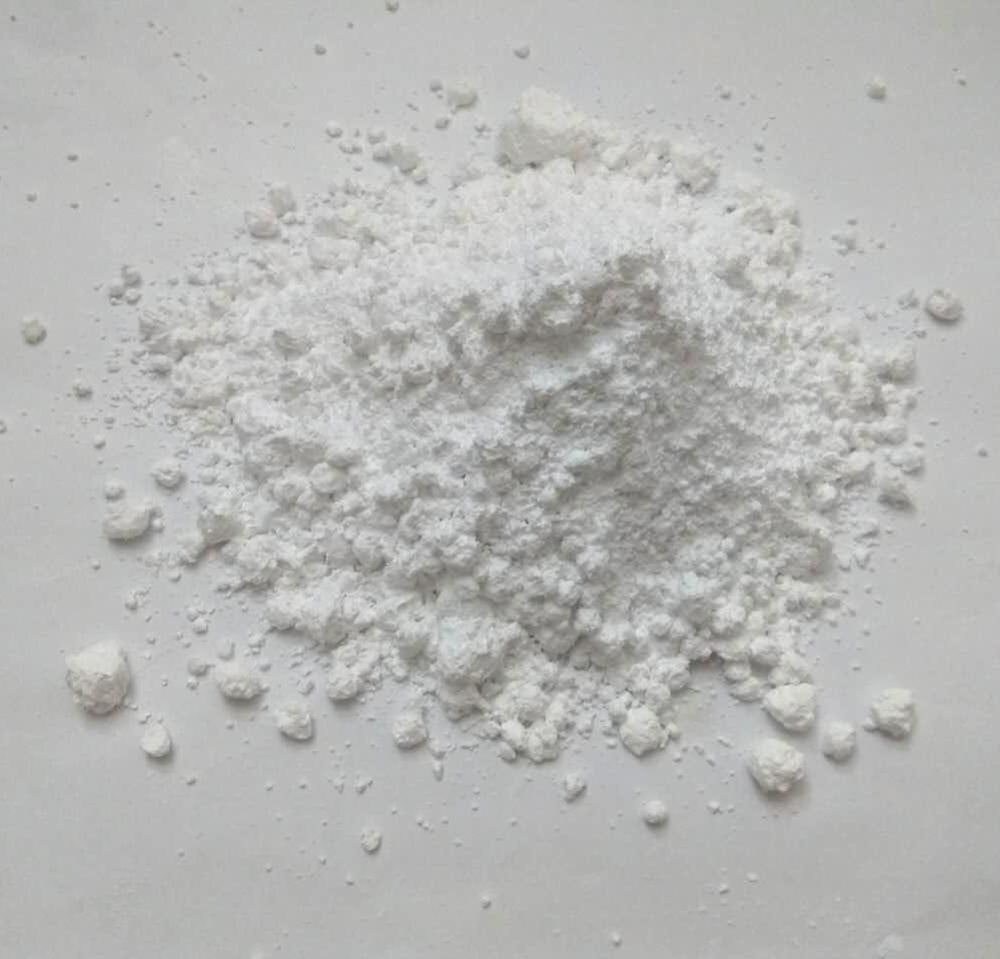

Microsilica – pozzolanic substance with a high content of SiO2 – is a fine-dispersed gray dust of a spherical shape and a smooth surface.

Dust is extracted from the exhaust gases of furnaces during the smelting of metallurgical silicon and ferrosilicon.

Concrete of high strength and water resistance, as well as high corrosion resistance, is made from microsilica. Replacing 15% of cement with microsilica increases water resistance of concrete by several tens of times. In addition, it leads to a 20% increase in compressive strength and a threefold decrease in water absorption.

Fine microsilica particles (average about 0.1 micron, which is 100 times smaller than the average grain size of cement) densely fill the volume between coarse cement particles (microfilling ). This contributes to an increase in strength due to the secondary pozzolanic reaction.The increased density and low permeability of cement stone, together with microsilica, also provides good frost resistance.

The rheologically stable structure of concrete with microsilica helps to reduce air loss during vibration and transport.

The use of microsilica makes it possible to obtain concrete from simple materials, that provides unique possibilities for constructing, as well as high performance characteristics:

– Abrasion resistance

– High strength, increased cohesion and non- separation

-Reduced consumption of cement (from four hundred to two hundred and fifty kg/m3)

– Anti-corrosion resistance

– 50 % water permeability, 100% increase in sulfate resistance

– Frost resistance -Durability

production of mortars and concretes,

production of insulating materials,

production of ceramic and refractory products,

other industrial application.